How the Cable Attaches

Machine Swage Terminal

![]()

Machine Swage (swaj): Fittings are attached to the cable by means of a cold forming press. The completed fitting has a smooth uniform appearance and will develop full cable strength. Swaging services can be performed by professional riggers and sling manufacturers.

Hand Crimp Terminal

![]()

Hand Crimp: Hand Crimp is available in 1/8” & 3/16” cable only. Fittings are attached to the cable using a simple hand tool (allows field installation). The completed fitting will provide approximately 65-70% of the 7×7 cable strength. We can provide the necessary tool.

Mechanical Terminal

![]()

Mechanical: Fittings are available for all cable sizes and are attached with simple hand tools. Mechanical fittings are more expensive than other means of attachment but develop full cable strength.

Cable Selection

Description of Wire Construction:

Generally 1/8”, 3/16”, or 1/4”, 1×19 stainless steel cable is chosen for most railing applications. 3/16” cable is the most popular size for general applications. 1/4” cable is for high traffic applications.

1 x 19 – Semi-rigid…used for straight runs

7 x 7 – Semi-flexible…used for short runs and decorative corners

7 x 19 – Flexible…used for decorative purposes

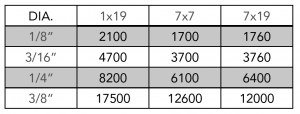

Stainless Steel Wire Rope

Breaking Strength

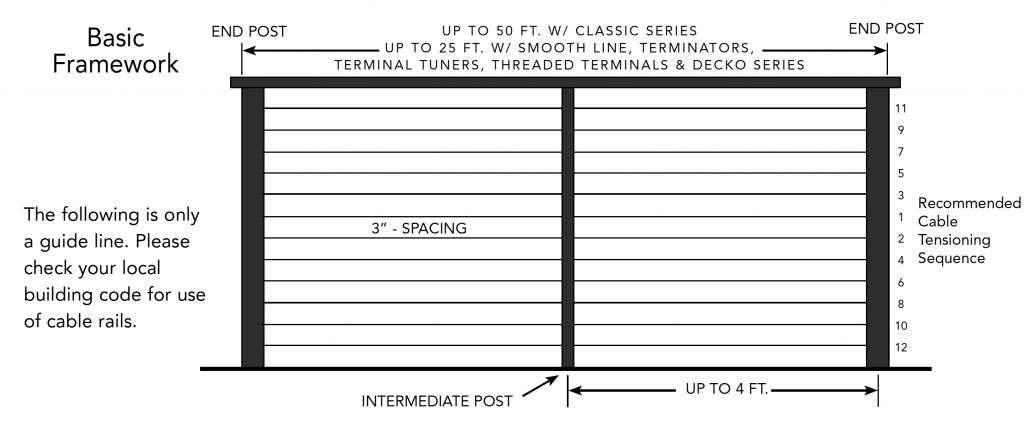

Suggested Railing Framework

Framework:

End posts and corners need to be made from the following minimums:

• Round Pipe 1-1/2” ID Schedule 80

• Square Tube 2” X 2” X 1/4” Wall

• Angle Iron 2” X 2” X 1/2”

• Flat Bar 2” X 1” (widest dimension should be inline with cable tension)

• Wood Post 6” X 6”

Please Note: Johnson Architectural Hardware does not make framework. Framework needs to be made by a steel fabricator.